Unique and Patented Technologies for the Future of Bioprocessing

CP Biotools LLC is a growing company committed to answering the challenges of life-science laboratories and bio-pharmaceutical manufacturers worldwide.

The company is in the process of developing products derived from the patents it owns, and continues to push the boundaries of bioprocessing technology to provide new cost-effective alternatives that provide a high rate of reliability.

Currently in Development

Novel Single-Use Perfusion Bioreactor Without a Mixing Impeller that Operates with Reduced Shear and Lower Cost

Design parameters for CP Biotools’ Single-Use Bioreactor (SUB) include:- Simple bag-style design with liquid and gas diffusers

- Eliminates mechanical mixing

- Ability to utilize single-use pH and dissolved oxygen probes that eliminates the need for an autoclave

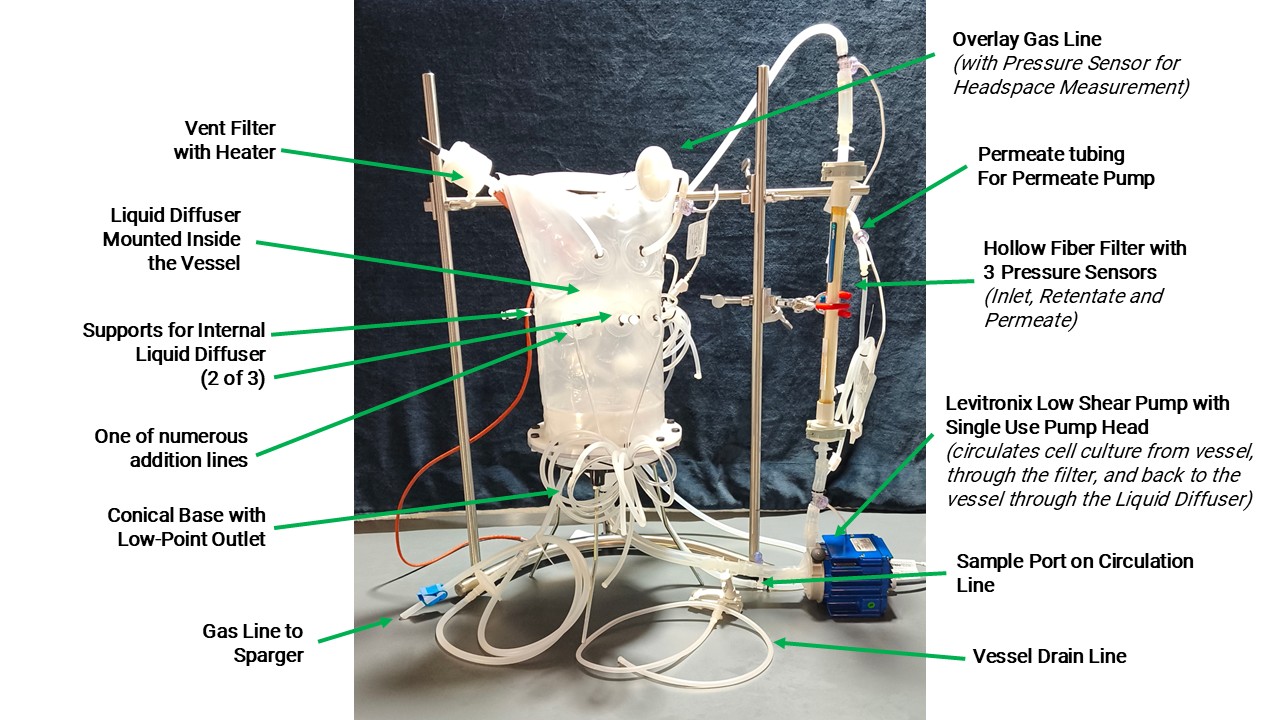

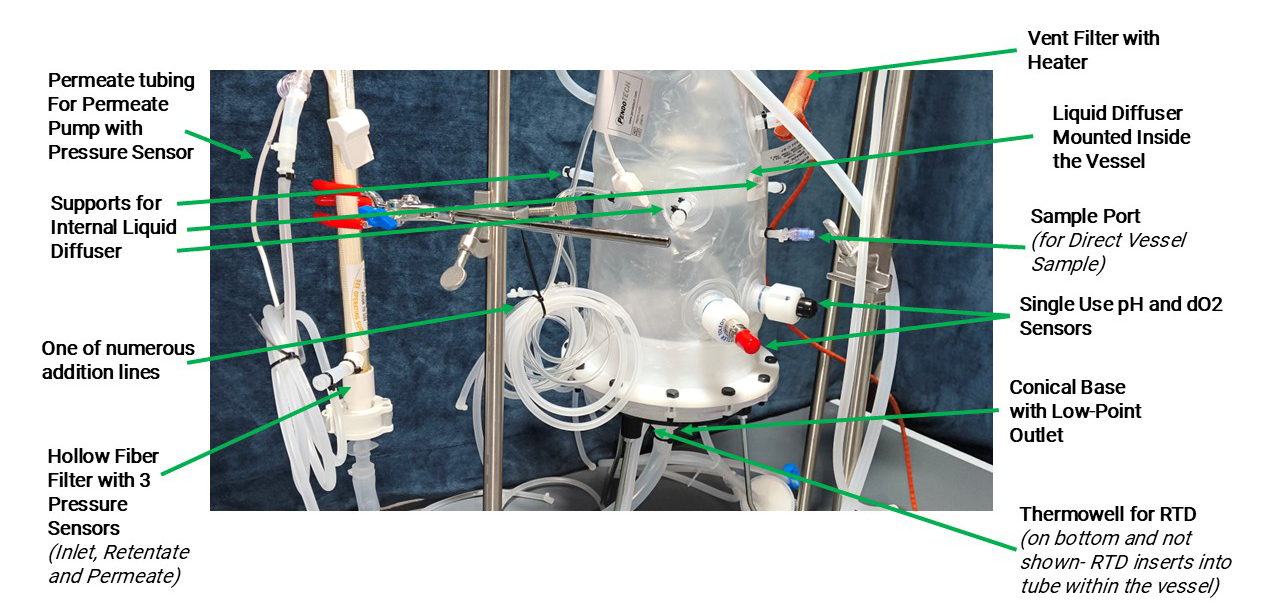

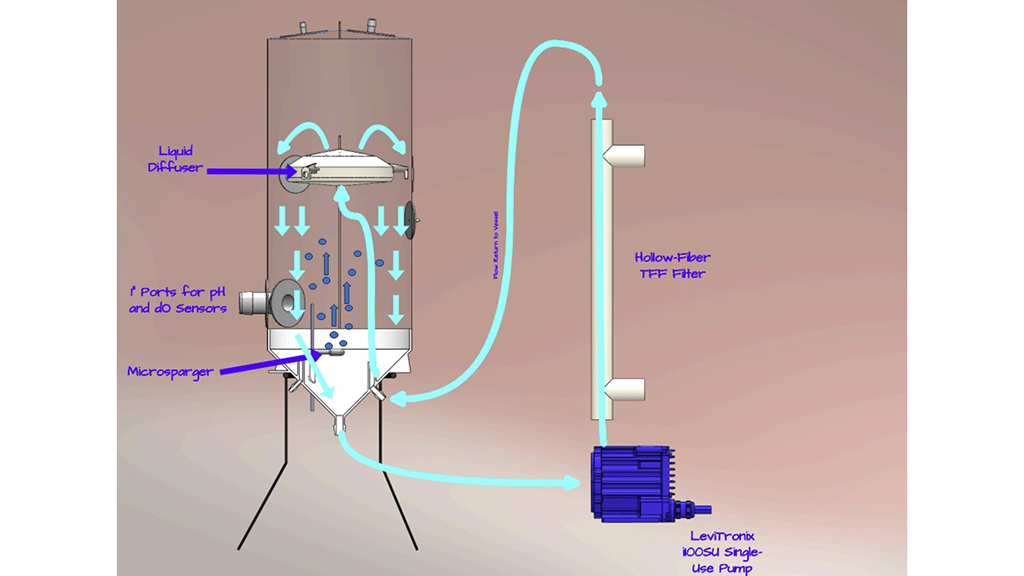

Earlier product designs tested with CHO cells contained rigid 3D printed parts to mimic the shape of the final design and this was followed by a bag version tested in a batch CHO cell culture. The final design is a simple bag-style design with a liquid diffuser and a gas sparger and no internal moving parts and a hollow fiber for cell retention for the continuous perfusion mode. The bag is sealed to the plastic rigid base via a custom designed film to plastic heat sealing tool and the bag portion has port plates sealed into it. The bag portion incorporates a number of key components including ports to receive the single use pH and DO probes, ports to support the liquid diffuser, and additional ports. The rigid base contains the thermo-well for a temperature probe, the liquid drain, a port for the liquid return line, and the gas inlet to the gas sparger.

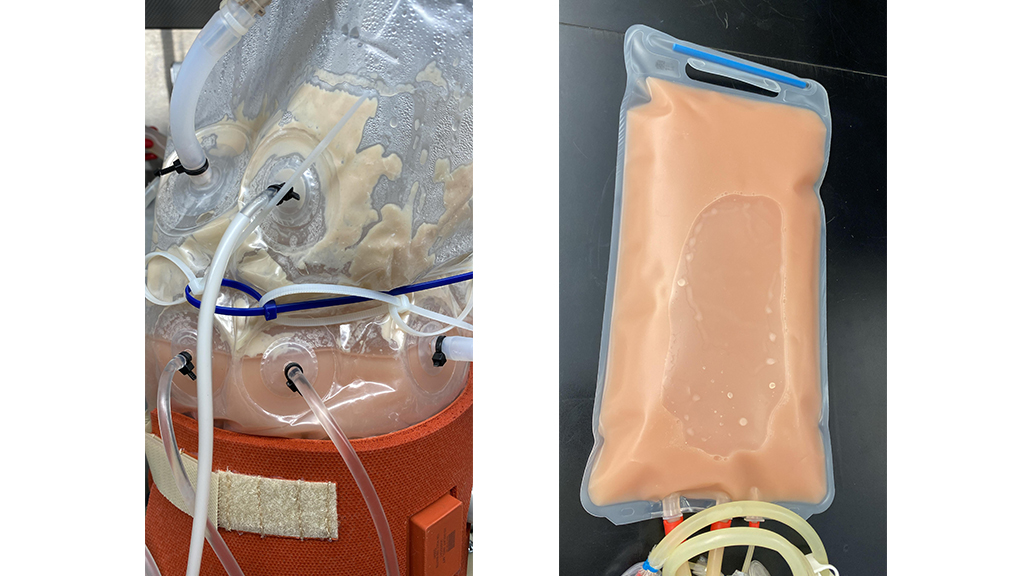

Both the counter-current flow of gas rising from the sparger and liquid flowing to the bottom of vessel and the air liquid interface of the fountain enhance mixing and Kla. Extensive design testing and optimization have been completed using miscellaneous tools such as 3D printing, water runs to measure Kla, extensive physical measurements with different sensors. In addition, three CHO cell culture runs have been completed over the different design iterations in conjunction with Jefferson Institute for Bioprocessing at Thomas Jefferson University.

Successful Results

CP Biotools achieved very promising results on our initial run. After inoculation of the reactor with 1x10E6 cells, on Day 7, the cell density reached >45 million cells per mL in this initial run. This was accomplished in the fourth run of this bioreactor and the first perfusion run of its progressively iterative bioreactor design.

We challenged the standard design of single-use bioreactors by removing the mixing impeller entirely. Instead, our new design uses a liquid diffuser to create a “fountain” flow. This enhances oxygen transfer kLa while drastically reducing shear stress on cells.

Novel Single-Use Perfusion Bioreactor